Introduction

Cryogenic handling is a specialized and critical process that involves the safe management and storage of materials at extremely low temperatures, typically below -150°C. These temperatures are commonly used in a variety of fields, including medical applications, industrial manufacturing, and research. Proper cryogenic handling ensures that the materials and gases are maintained in a stable state, preventing accidents and ensuring the safety of personnel working with these substances.

Cryogenic handling requires a deep understanding of the materials involved, the equipment used, and the safety protocols needed to handle these substances safely. In this article, we will discuss the best practices for cryogenic handling, focusing on techniques and safety measures that reduce risks, prevent accidents, and maintain efficient operations.

1. Understanding Cryogenic Materials

Before delving into the specifics of cryogenic handling, it’s essential to understand what cryogenic materials are and their properties. Cryogenic materials are typically gases or liquids that exist at temperatures far below freezing, often used in applications such as liquid nitrogen, liquid oxygen, and liquefied natural gas (LNG). These materials can cause significant harm if not handled correctly due to their extremely low temperatures and potential for rapid expansion.

Key cryogenic materials include:

- Liquid Nitrogen (LN2) – Used in a variety of industries, including medical applications for cryopreservation and in food processing for freezing.

- Liquid Oxygen (LOX) – Often used in industrial processes and medical applications for oxygen therapy.

- Liquid Helium (LHe) – Commonly used in cryogenic cooling systems and scientific research.

- Liquefied Natural Gas (LNG) – Used as a clean fuel source for energy production and transportation.

Each of these substances has unique properties that must be considered during cryogenic handling. Liquid nitrogen, for example, is non-flammable but can cause severe frostbite upon contact with skin. Liquid oxygen, on the other hand, is highly reactive and can increase the combustibility of materials.

2. Cryogenic Handling Equipment

Cryogenic handling requires specialized equipment that is designed to handle these extreme temperatures safely. The following is a breakdown of essential cryogenic equipment:

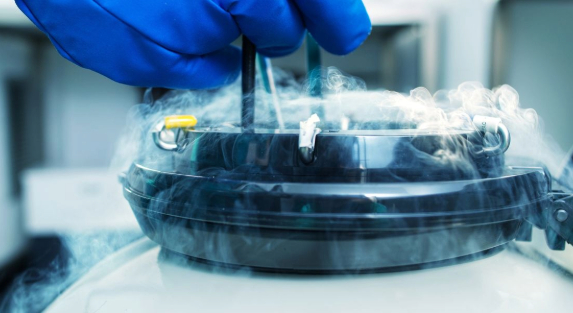

- Cryogenic Storage Tanks: These tanks are designed to store cryogenic liquids at low temperatures. They are typically insulated and can be pressurized to keep gases in liquid form.

- Cryogenic Pumps: Used to transfer cryogenic fluids from one container to another. These pumps are designed to maintain the extremely low temperatures of the fluids during transfer.

- Cryogenic Dewars: These are vacuum-insulated containers that are often used for storing smaller quantities of cryogenic liquids, such as liquid nitrogen or oxygen.

- Safety Valves and Pressure Regulators: These devices ensure that the cryogenic liquid does not exceed safe pressure levels, which could lead to an explosion or rupture of the container.

- Cryogenic Gloves, Goggles, and Face Shields: These are used to protect workers from exposure to cryogenic materials. Given the risk of frostbite and damage to eyes and skin, PPE is a critical part of the process.

The equipment must be regularly inspected and maintained to ensure its functionality, preventing leaks or accidents that could result from faulty equipment.

3. Personal Protective Equipment (PPE) for Cryogenic Handling

When handling cryogenic materials, the risk of injury is high, which is why the use of appropriate PPE is one of the best practices in cryogenic handling. Key personal protective gear includes:

- Cryogenic Gloves: These specialized gloves are made of insulated materials that protect the hands and forearms from the extreme cold of cryogenic fluids.

- Cryogenic Goggles or Face Shields: These protect the eyes and face from exposure to cryogenic vapors and splashes, preventing frostbite or eye injury.

- Insulated Boots and Pants: These are designed to prevent cold burns on the legs and feet, which are common when working with cryogenic liquids.

- Full-body Protective Suits: In high-risk environments, workers may wear full-body suits to shield themselves from the dangers associated with cryogenic materials.

It’s important to ensure that all personnel involved in cryogenic handling are equipped with the appropriate PPE, and that they are trained in its proper use and maintenance.

4. Proper Storage and Transportation of Cryogenic Materials

Proper storage and transportation of cryogenic materials are essential for safe operations. The storage tanks, cylinders, and containers used must be equipped with safety mechanisms like pressure relief valves, insulation, and monitoring systems to ensure the materials remain at stable temperatures.

- Storage: Cryogenic liquids should be stored in insulated containers that minimize the heat transfer into the system. This will keep the materials at their required temperature. Regular checks should be made to ensure the integrity of these containers, as even minor damage could lead to leaks or temperature fluctuation.

- Transportation: When transporting cryogenic materials, containers should be secure and monitored to ensure they remain intact throughout the journey. Vehicles used for transportation should be equipped with emergency shutoff systems and safety features to mitigate risks in case of an accident.

The key to safe cryogenic handling during storage and transportation lies in ensuring that containers are maintained at the correct temperature and that any safety features are regularly checked and tested.

5. Cryogenic Handling Procedures for Safe Operations

There are several handling procedures that should be followed to ensure safety during cryogenic operations. These include:

- Ventilation: Cryogenic gases, such as oxygen or nitrogen, can displace oxygen in confined spaces, leading to asphyxiation risks. Proper ventilation must be ensured in areas where cryogenic materials are stored, used, or transported.

- Leak Detection: Cryogenic liquids must be handled in systems that are designed to detect and prevent leaks. Pressure sensors, alarms, and other monitoring systems can be used to identify leaks early, reducing the risk of a hazardous situation.

- Safe Transfer Techniques: When transferring cryogenic liquids from one container to another, ensure that the transfer process is done slowly and carefully. Fast transfers can lead to pressure surges, spills, or the splashing of cryogenic fluids.

Following standardized operating procedures (SOPs) is essential for the safe handling of cryogenic materials, reducing the likelihood of accidents and ensuring that personnel remain safe.

6. Training and Education for Cryogenic Handling

One of the most important aspects of cryogenic handling is ensuring that all personnel involved are properly trained. This includes:

- Safety Training: Workers must understand the risks associated with cryogenic materials and know how to handle them safely. This includes recognizing the symptoms of cryogenic exposure, understanding the proper response protocols, and knowing how to use emergency equipment.

- Operational Training: Workers must also be trained in the proper operation of cryogenic equipment, including storage tanks, pumps, and transfer systems.

- Emergency Response: Training should include emergency response protocols in case of equipment failure, spills, or exposure incidents.

Regular refresher courses and safety drills should be conducted to keep the workforce updated on the latest cryogenic handling techniques and to ensure that they remain prepared for emergency situations.

7. Emergency Protocols and First-Aid Measures

Even with the best preparation, accidents can happen. In cryogenic handling, exposure to cold materials can cause severe frostbite, hypothermia, or asphyxiation. It is essential to have a detailed emergency protocol in place, which includes the following measures:

- First-Aid for Cryogenic Burns: In the event of frostbite or cold burns, immediate first aid should be administered. This includes removing the person from the source of the cryogenic material, warming the affected area slowly, and seeking medical attention.

- Asphyxiation: In areas where cryogenic gases may displace oxygen, having oxygen tanks and other life-saving equipment readily available is critical. Emergency exits should be clearly marked, and workers should be trained in using rescue equipment.

Having first-aid kits, oxygen tanks, and trained emergency responders on-site is essential in maintaining safety.

8. Cryogenic Safety Regulations and Standards

Several safety standards and regulations govern the safe handling of cryogenic materials. These include guidelines set by organizations like the Occupational Safety and Health Administration (OSHA), National Fire Protection Association (NFPA), and American National Standards Institute (ANSI).

These organizations provide comprehensive guidelines on:

- Proper container and tank construction

- The design of cryogenic handling systems

- Minimum safety distances

- Procedures for emergency response

Adhering to these regulations ensures that cryogenic materials are handled safely and in compliance with national and international standards.

Conclusion

Proper cryogenic handling is vital for ensuring safety in industries that deal with cryogenic materials. By following the best practices outlined in this article, including understanding the materials, using the right equipment, employing personal protective gear, and ensuring proper training, companies can mitigate risks associated with cryogenic operations. With advancements in technology and ongoing training, cryogenic handling will continue to improve, making it a safer and more efficient practice for workers and industries alike.

(2).png)

.png)

(1).png)

.png)