The safety and ongoing functionality of high-performance labs depend entirely on the proper condition of their gas distribution system which supports experiments' reliability results. The successful design of a gas distribution network depends on the integration of essential elements which include pressure regulation along with gas purity control and precise system regulation and sensors for monitoring and proper selection of materials and piping systems. Security becomes especially vital for reactive or toxic and flammable gases because any flawed system can cause equipment failure along with hazardous conditions or dangerous outcomes.

The trusted gas distribution solutions provider Ziebaq offers unmatched ownership in upstream and downstream system design and supporting installation of complete gas distribution systems. The team collaborates with clients to identify application requirements for creating customized engineered systems that highlight safety measures along with performance and scalability.

All Ziebaq gas distribution systems conform to the highest requirements in the industry. Plug-and-play solutions from our company give clients continuous high-pure gas delivery with minimal staff interaction throughout generation and distribution. The model operates with maximum efficiency and extended reliability therefore it serves essential research needs across pharmaceutical labs and research institutions while meeting requirements for industrial testing facilities and advanced analytical environments.

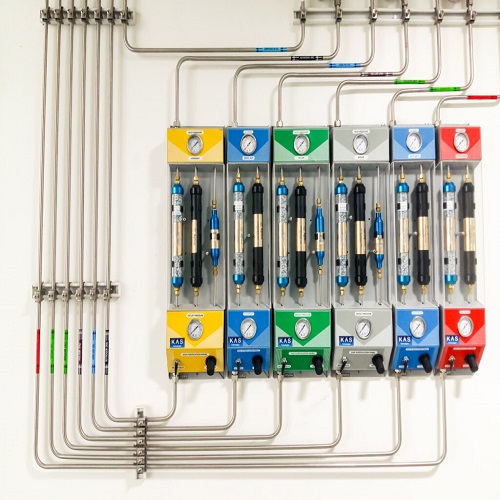

The Palletized Cylinder Manifold Systems organizes multiple gas sources through a secure handling system.

Multi-Cylinder Manifold Systems – Ensure continuous supply and seamless switching across multiple cylinders.

Centralized Distribution Systems – Optimize gas flow from a centralized source to multiple laboratory stations.

Auto-Changeover Systems permit unattended source transitions which produce neither pressure fluctuations nor operational interruptions.

Automatic Shut-Off Systems – Enhance safety with instant shutdown in case of emergency or failure detection.

A two-step procedure of Auto-Purge and Check Systems removes pollutants from gas delivery lines during the delivery cycle.

Volumetric Flow Control with Sensors – Deliver precise gas volumes with intelligent sensor feedback and real-time monitoring.

A secure connection system allows proper calibration between GC/MS and ICP/MS and LC/MS instruments along with various other high-sensitivity instruments.

Ziebaq builds its gas lines from stainless steel tubing which underwent cleaning procedures and finished with either chemical passivation or electro-polishing processes. The selection process includes materials that surpass all international safety standards for cleaning capability and resistance to corrosion and maintain stable pressures.

Through its modular future-ready design Ziebaq provides laboratory solutions which guarantee both efficiency and adaptability as well as safety for laboratory equipment. Ziebaq enables customers to obtain either minimal gas setup solutions or comprehensive integrated distribution platforms which benefit from engineered excellence alongside exceptional technical guidance and extensive industry knowledge.

High-purity gas is essential for ensuring accurate and repeatable results in sensitive applications such as GC/MS, ICP/MS, LC/MS, and other analytical techniques. Contaminants can compromise the integrity of data and damage sensitive equipment.

Common gases include Nitrogen (N₂), Hydrogen (H₂), Helium (He), Argon (Ar), Carbon Dioxide (CO₂), and specialty mixed gases, depending on the application.

Safety is maintained through pressure regulators, leak detection, automatic shut-off valves, alarms, and compliance with standards like NFPA, ISO, and local safety codes. Proper system design and regular maintenance are also critical.

Typical components include:

Gas source (cylinder, bulk tank)

Manifolds and regulators

Valves and piping (usually stainless steel or copper)

Delivery panels

Pressure monitoring and control devices

Alarm and control systems

System design depends on:

Type and number of gases used

Required flow rate and pressure

Purity requirements

Application type (e.g., analytical, synthetic, cryogenic)

Layout and size of the lab

A site assessment by professionals is often recommended.

Regular inspections are recommended—typically every 6 to 12 months depending on usage, gas types, and safety requirements. Leak checks, pressure calibration, and component integrity tests are part of standard maintenance routines.

Yes, many gas distribution systems are designed with modular components, allowing for easy expansion or upgrades as your laboratory’s needs grow.